Servicing A Diesel Generator: Everything You Need To Know

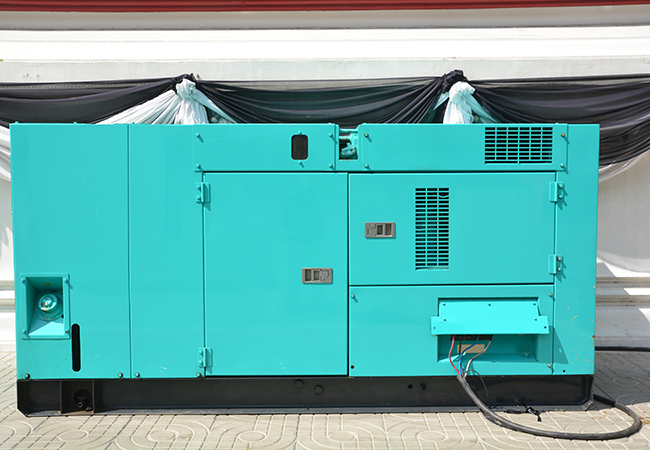

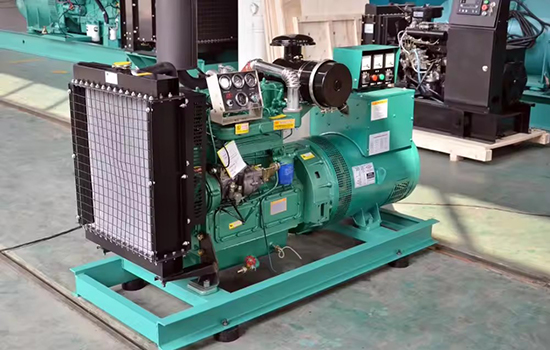

Diesel generators are crucial in providing reliable power in various settings, from emergency backup systems to remote off-grid locations. To ensure the longevity and optimal performance of a diesel generator, regular maintenance is essential.

How to Choose Essential KnowledgeIn this blog post, we’ll delve into everything you need to know about servicing a diesel generator, covering key aspects such as routine checks, preventive maintenance, and troubleshooting.

Routine Checks

Conducting regular checks on your diesel generator is imperative to the overall health of your unit. These checks can extend the lifespan of your generator exponentially simply because you can spot malfunctions in your system before they even occur.

If you would like a team of professionals to conduct these maintenance checks, FotePower is here to help! Our team of experienced generator technicians understand the inner workings of these machines like no other so if you are not familiar with your generator, be sure to give us a call!

Oil and Filter Changes

Regular oil changes are fundamental for the proper functioning of a diesel generator. The oil lubricates the engine, reducing friction and heat. Over time, oil becomes contaminated with particles and loses its effectiveness.

Therefore, it is crucial to change the oil at recommended intervals, typically every 100 to 200 hours of operation. Additionally, don’t forget to replace the oil filter during each oil change.

Fuel System Inspection

Diesel generators rely on a clean and efficient fuel system. Inspect the fuel lines, filters, and injectors regularly. Replace fuel filters as recommended by the manufacturer and ensure that the fuel tank is free of water and contaminants.

Air System Maintenance

A diesel generator’s performance depends on an adequate air supply. Check and clean the air filter regularly to prevent the buildup of dirt and debris. A clogged air filter can lead to reduced efficiency and increased fuel consumption.

Preventive Maintenance

Much like routine checks, preventive maintenance services involve locating any disruptions and faults in your system before they have the chance to become even more serious. Certain faults can be detrimental to your generator over time so conducting regular maintenance checks prevents this from happening.

This is something that our team can do for you as we look to assist as many people across the EUROPE with their generator issues as possible.

Cooling System Checks

The cooling system is critical for preventing the generator from overheating. Regularly inspect the radiator, coolant levels, and hoses. Clean the radiator fins from dust and debris, and replace the coolant at the recommended intervals to prevent corrosion and maintain proper temperature regulation.

Regularly check the coolant level in the radiator or coolant reservoir. The coolant is a crucial component for dissipating heat from the engine. Ensure that the coolant level is within the recommended range, and top it up with the appropriate coolant mixture if necessary.

The quality of the coolant is vital for effective heat dissipation and corrosion prevention. Check the condition of the coolant for signs of contamination, degradation, or discoloration. If the coolant appears dirty or shows signs of deterioration, it may be necessary to flush and replace it according to the manufacturer’s recommendations.

Battery Maintenance

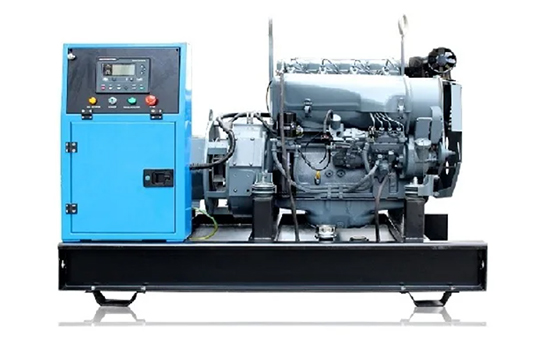

Diesel generators use batteries to start the engine, so it’s vital to check the battery’s condition regularly. Inspect for corrosion on terminals, clean them, and ensure the battery is charged. Consider load testing the battery periodically to assess its overall health.

Diesel generators use batteries to provide the initial electrical power needed to start the engine. If the battery is not in optimal condition, it may fail to deliver the required cranking power, leading to difficulties or even failure in starting the generator. Regular maintenance ensures that the battery is charged and can supply sufficient power for engine ignition.

These components are particularly important in electrical generators as they are the main driving force behind the power being generated from the unit itself.

Tightening and Inspection of Components

Vibrations during operation can lead to loose bolts and connections. Regularly inspect and tighten all nuts, bolts, and electrical connections. Pay close attention to the drive belts and replace them if they show signs of wear or damage.

Governor and Control Panel Inspection

The governor regulates the engine speed, and the control panel is the brain of the generator. Ensure that both are functioning correctly. Test the governor’s response to load changes, and check the control panel for any error codes or anomalies.

Troubleshooting

If your generator maintenance has not worked or you are beginning to experience issues before your preventative measures can take place, you may be in need of further measures such as repairs and replacements, this is another aspect of our professional service.

When troubleshooting the issues that occur in your generator it is important to take extra care so as to not exacerbate the problem or cause new ones entirely. This is why we offer an expert-tailored repair service to clients to make sure that this risk is minimized.

Unusual noises can be indicative of underlying issues. Pay attention to any knocking, rattling, or grinding sounds as these may suggest problems with the engine, alternator, or other components. Investigate and address the root cause promptly to prevent further damage.

Diesel generators should emit clear exhaust without excessive smoke. If you notice unusual smoke colors or patterns, it may indicate fuel combustion issues, air intake problems, or other issues. Investigate and resolve the source to maintain optimal performance and reduce environmental impact.

Conclusion

Regular and thorough servicing is crucial for ensuring the reliable and efficient operation of a diesel generator. By adhering to routine checks, preventive maintenance measures, and addressing any troubleshooting promptly, you can extend the lifespan of your generator and minimize the risk of unexpected breakdowns.

Remember to follow the manufacturer’s guidelines and consult with a qualified technician for complex maintenance tasks. With proper care, your diesel generator will continue to provide the power you need, whenever you need it.

If you are in need of any support regarding your generator unit whether you own a portable generator or a large, whole-house unit, our team are available to assist you with any repairs or maintenance as well as finding a new unit to replace your old one.

GENERATORS

- 1000KVA SHANGCHAI DIESEL GENERATOR

- 62.5KVA WEIFANG DIESEL GENERATOR

- 30KVA KOFO DIESEL GENERATOR

- 625KVA DOOSAN DIESEL GENERATOR

- 650KVA WEICHAI DIESEL GENERATOR

- 65KVA YUCHAI DIESEL GENERATOR

- 60KVA DEUTZ DIESEL GENERATOR

- 20KVA DEUTZ DIESEL GENERATOR

- 800KVA SILENT GENERATOR

- 13KVA PERKINS DIESEL GENERATOR

- 400KVA CUMMINS DIESEL GENERATOR

LATEST NEWS

-

Advantages Of A Cummins Generator

2024-02-25

-

How Do Portable Generators Work?

2024-02-25

-

Servicing A Diesel Generator: Everything You Need To Know

2024-02-25

FEATURED PRODUCTS

-

1000KVA SHANGCHAI DIESEL GENERATOR

FP-3000GFSC

-

62.5KVA WEIFANG DIESEL GENERATOR

FP-50WEF

-

30KVA KOFO DIESEL GENERATOR

FP30KOF

-

625KVA DOOSAN DIESEL GENERATOR

FP625DOO

-

650KVA WEICHAI DIESEL GENERATOR

C22D5 1PH

-

65KVA YUCHAI DIESEL GENERATOR

FPY50

-

60KVA DEUTZ DIESEL GENERATOR

FP60DEU

-

20KVA DEUTZ DIESEL GENERATOR

FP20DEUTZ

-

800KVA SILENT GENERATOR

FP800RS

-

13KVA PERKINS DIESEL GENERATOR

FP13RS-403A

-

400KVA CUMMINS DIESEL GENERATOR

FP400RSC

For more information about our POWER SOLUTIONS

Get in touch to speak to the team.